A lot of the time we can boil things down to the basics when it comes to PC hardware. In general: more transistors, more power; more power, more heat; you get the idea. And today I'm reminded of another basic rule of hardware design: more surface area means better heat dissipation.

Upon a first reading of the press release its wording led me assume that the "micro-pin fins" in the product somehow embed into whatever chip is being cooled, and that would be mighty impressive.

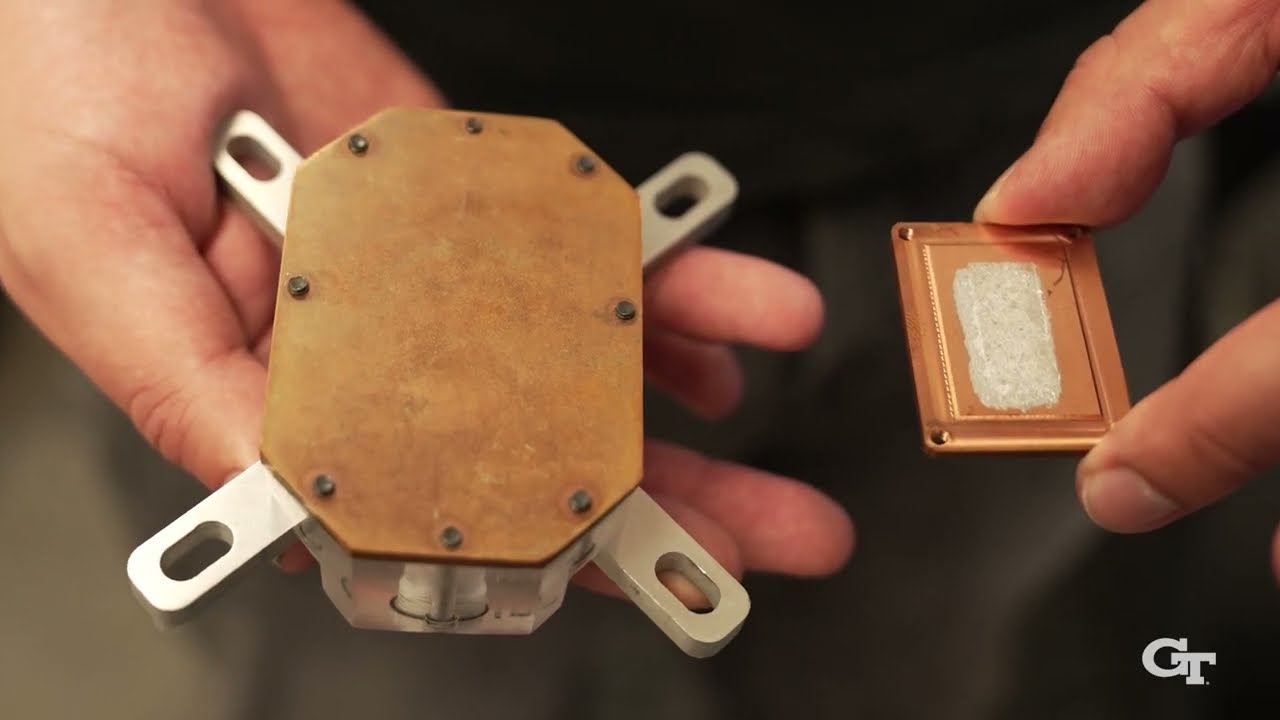

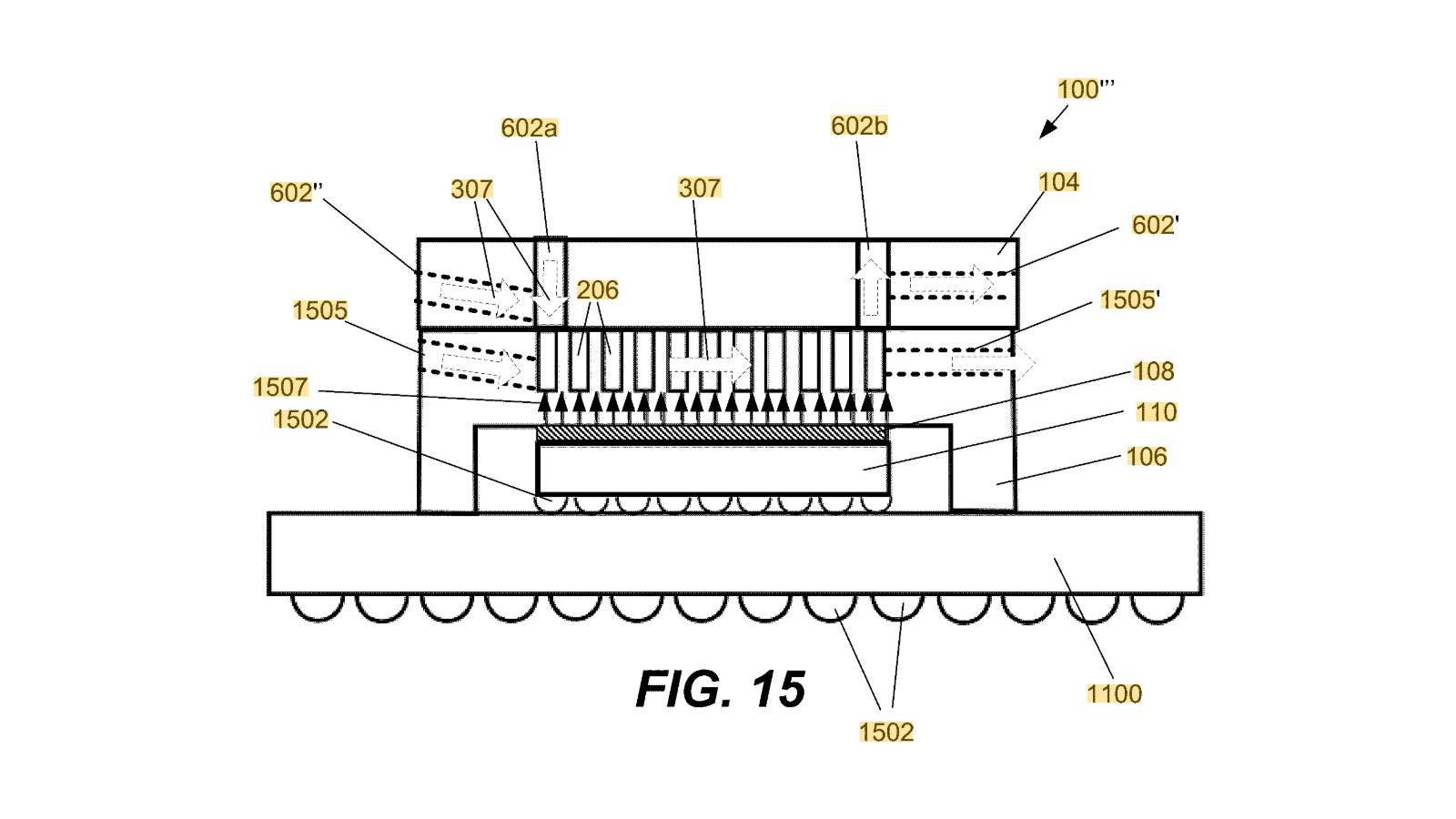

But actually it looks like these micro-pin fins sit within the waterblock, facing away from the chip, turning the entire thing into something akin to a heatpipe that's been flattened out. The liquid flows through and picks up the heat from the micro-pin fins.

This seems to me like a standard cooling affair but with tons more surface area for heat dissipation thanks to these little fins—the same principle that guides the design of a standard heatsink.

The other aspect of this is that, although it can be used on top of u31 เข้าสู่ระบบ a CPU's integrated heat spreader (IHS), it's meant to have "direct-die contact" but this, , "requires the use of liquid metal for the best results." And of course it will require delidding your CPU, the thought of which is sure to send shudders down many a PC builder's spine.

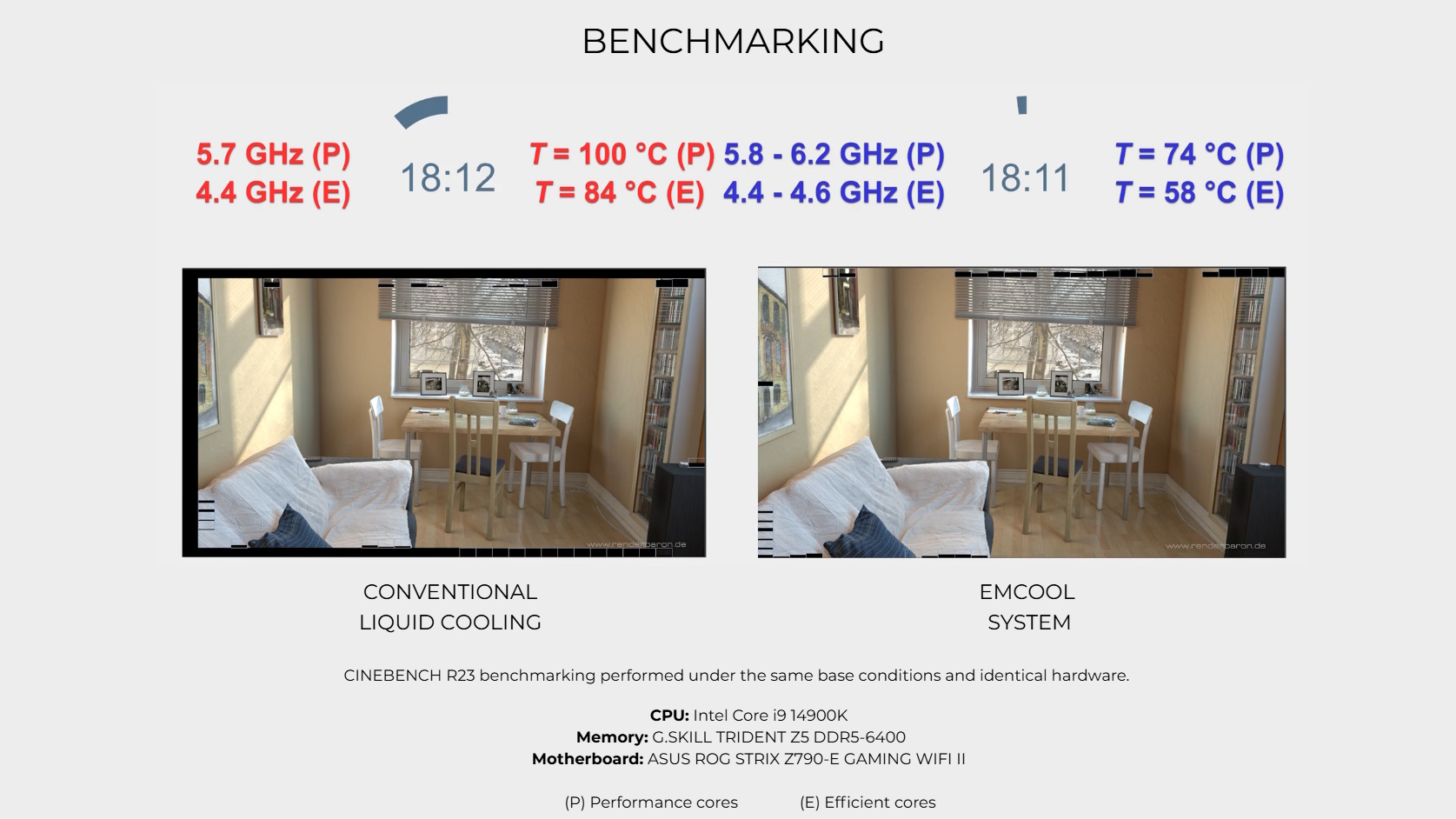

What's the end-result, you ask? The proof, as pretty much nobody ever says anymore, is in the pudding. According to EmCool's homepage visual, a Cinebench R23 benchmark showed much lower temperatures and no throttling with such a waterblock installed.

Without the waterblock, the Intel Core i9 14900K's P-Core temperature reached 100 °C and throttled speeds to 5.7 GHz vs the full 5.8–6.2 GHz at w69 slot ทาง เข้า 74 °C that was achieved with the waterblock on.

All of this serves to remind of the importance of the basics: increase heat transfer surface areas and temperatures will drop and performance might increase. Not quite the fin-into-chip tech that this at first seemed to be, but we don't need to reinvent the wheel to see real improvements, do we?